The Essential Parts of Hydraulic Excavators and Their Functions

Hydraulic excavators play a vital role in the construction and excavation industries. Understanding the parts of hydraulic excavators is key to appreciating their function and ensuring proper maintenance. This article will delve into the various components that make up hydraulic excavators, illuminating their functionalities and providing valuable maintenance tips.

Overview of Hydraulic Excavators

Hydraulic excavators are powerful machinery equipped primarily for digging and moving earth, but their versatility allows them to perform various tasks across construction sites. They utilize hydraulic systems to generate immense force and movement, allowing for the completion of heavy duties efficiently and effectively. The intricate design and engineering of excavators call for a deeper look into their components.

Main Components of Hydraulic Excavators

Let’s explore the essential parts of hydraulic excavators and their respective functions. This understanding is crucial for those involved in the operation, maintenance, and purchase of these machines.

1. The Boom

The boom is one of the most significant parts of hydraulic excavators, serving as the primary arm that connects the attachment to the machine's body. This component is crucial for reaching out and lifting heavy materials. The design of the boom can vary, with some models having a extendable boom for increased reach.

2. The Stick (or Arm)

The stick is the part that extends from the boom, giving additional reach and flexibility to the excavator. This component allows the operator to position the attachment closer or further away from the machine body. The stick plays a crucial role in digging and trenching operations.

3. The Bucket

The bucket is one of the most recognizable components of a hydraulic excavator. Designed for digging, scooping, and moving materials, the bucket comes in various shapes and sizes depending on the excavation needs. The right choice of bucket can enhance efficiency on-site dramatically.

4. The Cab

The cab houses the operator and contains the controls for operating the excavator. Safety features, visibility, and comfort are critical aspects of the cab design. Many modern cabs also incorporate advanced technology that enhances usability and operator performance.

5. The Tracks (or Wheels)

Tracks or wheels are essential for the mobility of hydraulic excavators. Tracks are generally preferred for improved stability and traction, especially in off-road conditions. Understanding the condition of the tracks is essential for ensuring the excavator's operational effectiveness.

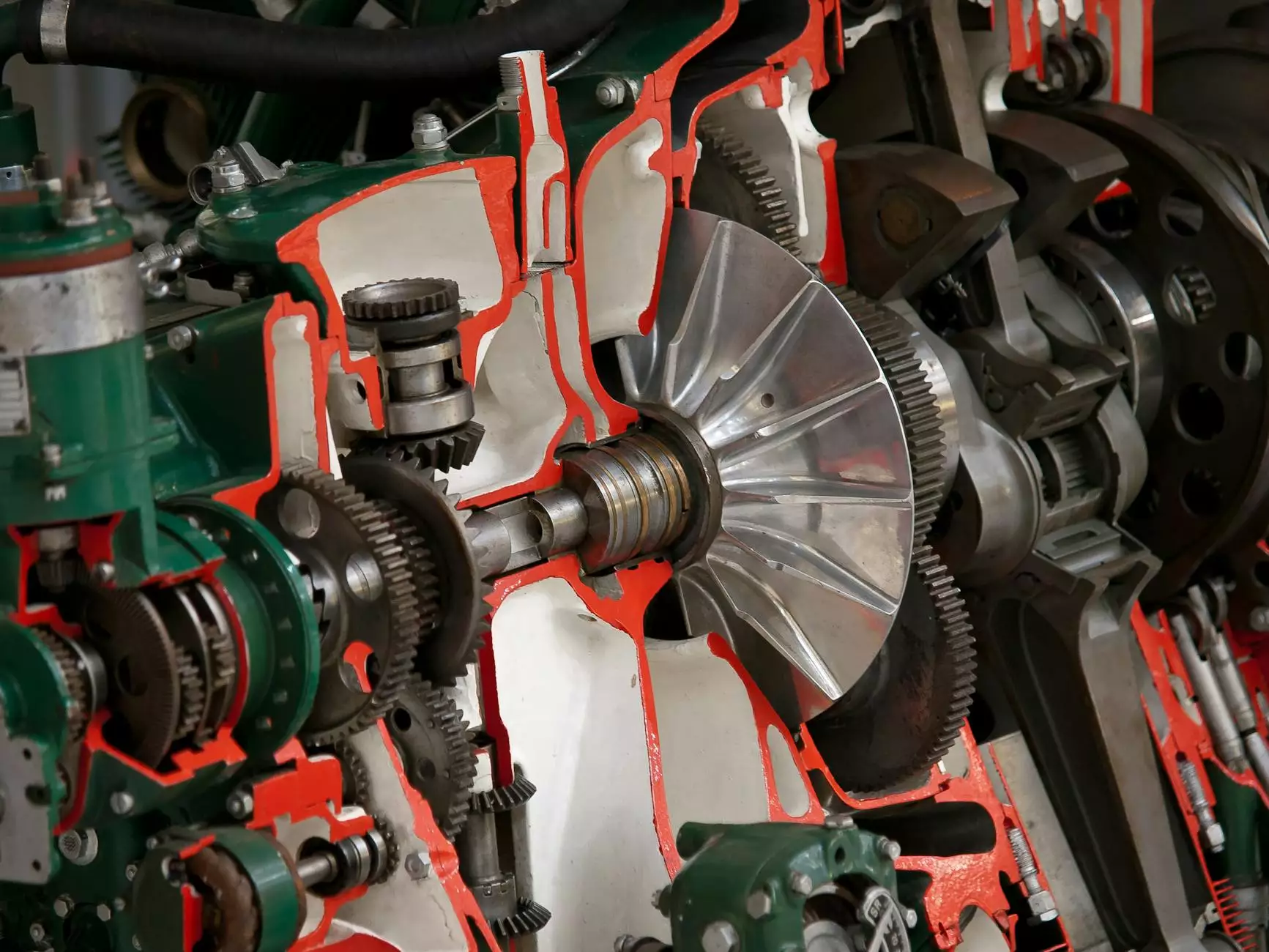

6. The Hydraulic System

The hydraulic system is the heart of the excavator, providing the power necessary for all movements. This system consists of hydraulic pumps, cylinders, and hoses that work together to convert hydraulic fluid power into mechanical energy. Proper maintenance of the hydraulic system is essential to avoid costly repairs and ensure smooth operation.

7. The Counterweight

To maintain balance during operations, a counterweight is located at the rear of the excavator. This component offsets the weight of the boom, stick, and bucket as materials are lifted. The size and weight of the counterweight are designed to enhance stability during digging and lifting activities.

How to Select Quality Hydraulic Excavator Parts

Choosing quality parts for hydraulic excavators is crucial for the longevity and performance of the machinery. Here are some guidelines to help make informed decisions:

1. Understand Your Needs

Assess the type of work your excavator will be doing and select parts that align with these requirements. For instance, if you are involved in heavy-duty excavation, opt for robust and durable components.

2. Research Reputable Suppliers

When purchasing parts, look for suppliers with a proven track record. A website like ShopHydraulicAmerica.com offers a range of quality parts specifically designed for hydraulic excavators and other machinery.

3. Check for Warranty and Support

Reputable suppliers will often provide warranties for their parts. Ensure that you understand the terms and that adequate customer support is available when needed.

Maintenance Tips for Hydraulic Excavators

Regular maintenance is vital for ensuring the longevity and efficiency of hydraulic excavators. Here are some practical tips:

1. Regular Inspections

Conduct frequent inspections of all major components, including the hydraulic system, boom, stick, and bucket. Look for signs of wear, leaks, or damage.

2. Fluid Checks

Regularly check hydraulic fluid levels and quality. Ensure that the fluid is clean and at the correct level to maximize system efficiency and prevent damage.

3. Keep it Clean

Keeping the excavator clean can help detect issues early. Remove mud, dirt, and debris from the tracks, engine compartment, and other areas.

4. Follow Manufacturer Guidelines

Always adhere to the manufacturer’s guidelines for maintenance and part replacement. This will help ensure that you are using the correct parts and techniques.

The Future of Hydraulic Excavators

The evolution of hydraulic excavators is ongoing, with new technologies enhancing their capabilities. Innovations in hydraulics, artificial intelligence, and automation are paving the way for more efficient excavation processes.

1. Smart Technologies

Modern excavators are increasingly equipped with smart technology that allows for remote monitoring and diagnostics, providing valuable insights into equipment health and performance.

2. Eco-Friendly Alternatives

The push for sustainability in construction is leading to the development of eco-friendly excavators that utilize alternative energy sources, reducing the carbon footprint of excavation tasks.

Conclusion

In conclusion, a comprehensive understanding of the parts of hydraulic excavators is essential for anyone involved in the machinery’s operation or maintenance. By knowing each component's function and making informed choices when selecting parts, operators can enhance performance, safety, and efficiency. Regular maintenance will ensure the longevity of your equipment, ultimately leading to a more productive and successful construction operation. Consider visiting ShopHydraulicAmerica.com for quality parts that keep your excavators running smoothly.